Laser cutting is known for its sharp, clean cuts but it can do more than just shape large pieces of metal or wood. With the right settings and setup, it can work on a very small scale too. Some industries need parts that are cut with incredible detail and accuracy, sometimes smaller than a grain of rice.

For those looking into laser cutting in Dubai, this level of precision is already being used in everything from electronics to fine jewelry.

How the Laser Gets So Precise:

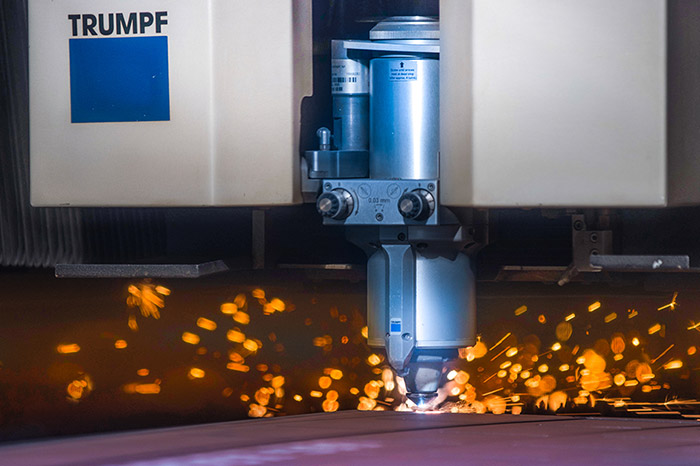

Laser cutting works by focusing a beam of light onto a tiny point. That point gets hot enough to melt or burn through the material. By making the beam very narrow and controlling its movement with advanced machines, it’s possible to cut shapes that are almost too small to see with the naked eye. The key is how well the machine controls speed, power, and focus.

Materials That Handle Micro Cutting Well:

Not all materials can handle tiny cuts. Metals like stainless steel and titanium are popular because they stay strong even when the cuts are small. Thin plastics, ceramics, and some types of glass are also used, depending on the industry. The quality of the material plays a big part in how clean the final cut looks. If the surface isn’t smooth or the material reacts poorly to heat, the results won’t be as accurate.

Used in High-Tech Industries:

You’ll find this level of accuracy in industries like medical devices, electronics, watches, and aerospace. In these fields, even a small flaw can cause a product to fail. Tiny filters, gears, or frames need to fit perfectly with other parts. Laser cutting allows this to happen without touching the material, which means there’s less chance of damage.

Clean Edges Without Extra Work:

When cutting small parts with traditional tools, the edges often need to be cleaned up afterward. Laser cutting avoids this by creating a smooth edge during the cut itself. That saves time and keeps the piece in better condition, especially when the parts are too small to handle easily.

Microscopic laser cutting may not be something most people think about, but it’s already shaping the world around us. It allows designers and engineers to push limits and build things that were once too small or too complex to make. And with access to advanced laser cutting, even local businesses can take advantage of this powerful tool.